To silence your noisy pump pad, start by adding mass with soundproofing materials like foam or mineral wool to absorb sound. use vibration isolators such as rubber mounts and flexible couplings to dampen vibrations. Create a sound-absorbing enclosure with acoustic panels placed near noise sources, and seal all gaps to prevent leaks. Regularly inspect and maintain mounts and bearings to keep noise levels low. Continue exploring for more effective acoustic tricks.

Key Takeaways

- Use layered soundproofing materials like foam, mineral wool, and vinyl around the pump pad to absorb and diffuse noise effectively.

- Install vibration isolators such as rubber pads or neoprene mounts to decouple pump vibrations from the pad and surrounding structures.

- Seal all joints and seams in enclosures to prevent sound leaks and improve overall noise attenuation.

- Mount the pump on a resilient, decoupled platform or isolation base to reduce vibration transmission.

- Regularly inspect and maintain mounts, dampers, and seals to ensure consistent noise reduction over time.

Adding Mass With Soundproofing Materials

Adding mass to your pump pad is one of the most effective ways to reduce noise. When you increase the weight, you make it harder for vibrations to transfer through the pad, which cuts down on sound transmission. You can do this by layering dense materials like mass-loaded vinyl or adding thick concrete or rubber mats. These materials absorb and block vibrations more effectively than lighter options. Guarantee the soundproofing materials are securely attached to the pad’s surface to prevent gaps that can let noise escape. The key is to choose high-density materials that resist movement, so your pump’s vibrations stay contained. Additionally, understanding the importance of soundproofing materials can help you select the most effective options for your setup. Using vibration dampening techniques can further enhance noise reduction. Incorporating proper installation methods ensures the longevity and effectiveness of your soundproofing measures. By adding mass, you create a sturdy barrier that considerably dampens the noise generated by your pump. Improving your knowledge of vetted materials for soundproofing can also contribute to more efficient noise control.

Using Isolation Mounts and Vibration Dampers

Proper mounting techniques are essential to reduce vibration transfer from your pump to its surroundings. Choosing the right vibration dampers can substantially minimize noise and movement. Ensuring your mounts are effective will make a noticeable difference in quieting your pump pad. Consulting best practices for vibration isolation can further enhance noise reduction. Incorporating essential oils for noise relief, such as lavender or peppermint, can also promote a calmer environment around noisy equipment. Additionally, understanding Gold IRA Rollovers can provide insights into diversifying investments, which may indirectly contribute to financial peace of mind and reduced stress caused by noisy pump operations. Paying attention to material options for mounts, like rubber or silicone, can improve vibration absorption and further decrease operational noise. Employing passive noise control techniques can complement vibration dampers for more comprehensive soundproofing.

Proper Mounting Techniques

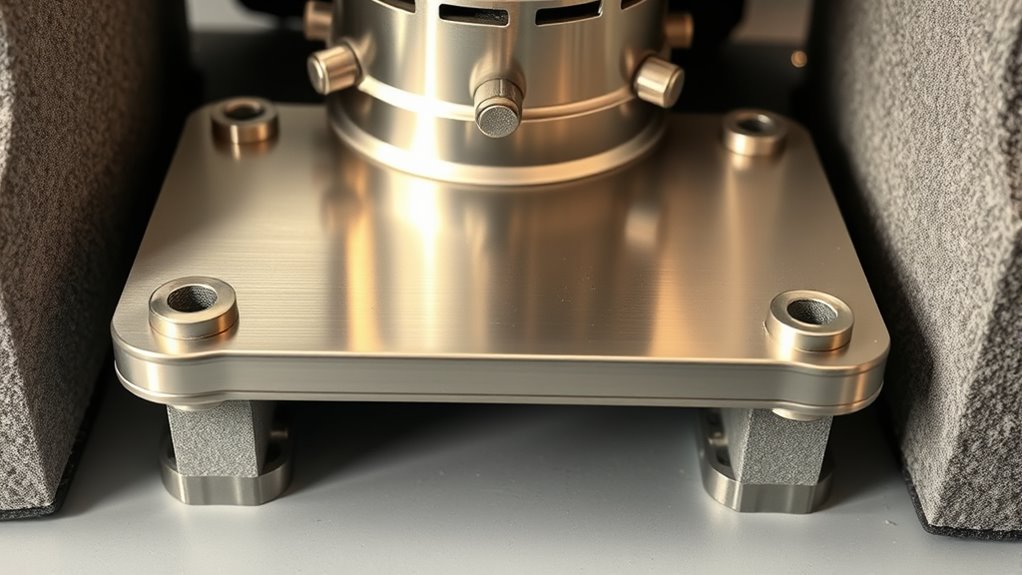

Using isolation mounts and vibration dampers is essential to effectively reduce noise from a pump pad. Proper mounting ensures these devices function at their best by minimizing direct contact between the pump and its support surface. Position the mounts evenly under the pump, avoiding areas that could cause instability or misalignment. Securely tighten all fasteners, but don’t overtighten, as this can compromise the mounts’ isolating properties. Use resilient materials like rubber or neoprene in the mounts to absorb vibrations effectively. Make sure the pad is level and stable, preventing any movement that could transfer noise. Regularly inspect the mounts for wear or deterioration, replacing them as needed. Incorporating mindfulness into maintenance routines can help identify early signs of wear, ensuring continued effectiveness. It is also beneficial to select mounts that are compatible with eco-friendly practices to support sustainable maintenance efforts. Additionally, choosing mounts with appropriate vibration absorption characteristics can enhance noise reduction and prolong equipment lifespan. Proper mounting techniques maximize vibration isolation, leading to a quieter, smoother operation. Moreover, considering HEPA filtration features in your maintenance tools can help keep the environment cleaner and reduce dust buildup that may affect mounting components. Incorporating a thorough inspection routine can further help detect issues early before they lead to increased noise or damage.

Selecting Effective Dampers

Choosing the right isolation mounts and vibration dampers is crucial for effectively reducing noise from your pump pad. Start by evaluating the weight and size of your pump to select mounts that can handle the load without compressing or failing. Rubber or neoprene mounts are common choices due to their excellent vibration absorption. For heavier equipment, consider spring-based dampers that offer better isolation. Confirm the mounts are compatible with your setup and provide sufficient clearance to prevent direct contact with the floor. Installing these dampers correctly can markedly cut down transmitted vibrations, minimizing noise. Remember, the more effective the dampers are at isolating vibrations, the quieter your pump pad becomes. Regularly inspect and replace worn dampers to maintain peak noise reduction.

Creating a Sound-Absorbing Enclosure

Choosing the right materials is key to building an effective sound-absorbing enclosure. You want options that trap noise without adding unnecessary weight or cost. Designing for maximum absorption guarantees your enclosure minimizes noise leaks and keeps your pump pad quieter. Incorporating soundproofing techniques can further enhance noise reduction by addressing potential gaps and resonances. Using materials with high sound absorption coefficients can significantly improve overall effectiveness by reducing sound reflections within the enclosure. Additionally, selecting materials with durability and ease of installation ensures your enclosure remains effective over time without requiring frequent repairs or modifications. Considering the properties of different soundproofing materials helps optimize your design for long-term performance. Selecting materials that are resistant to environmental factors also contributes to the longevity and consistent performance of your soundproofing solution.

Material Selection Strategies

Selecting the right materials is essential when creating a sound-absorbing enclosure for a noisy pump pad. Your goal is to choose materials that effectively dampen sound without adding excessive weight or cost. Acoustic foam panels, mineral wool, and mass-loaded vinyl are top options. Consider the density, porosity, and weight of each material to maximize sound absorption. For example, softer, porous materials absorb higher frequencies, while denser materials block more sound overall. Use the table below to compare key qualities:

| Material | Effectiveness |

|---|---|

| Acoustic Foam Panels | Better for high frequencies |

| Mineral Wool | Absorbs mid and high sounds |

| Mass-Loaded Vinyl | Blocks sound transmission |

Choosing materials with appropriate soundproofing qualities is crucial for tailoring your enclosure to your specific noise profile for best results. Additionally, understanding how these materials interact with the sound spectrum can help optimize their placement for maximum efficiency. For optimal performance, consider how the acoustic properties of each material influence the overall sound attenuation. Recognizing how the material density impacts sound absorption can further enhance your enclosure’s effectiveness. Moreover, selecting materials with suitable installation methods can improve the durability and performance of your soundproofing solution.

Design for Maximum Absorption

To maximize sound absorption, you should design the enclosure with multiple layers and strategic placement of absorbing materials. Start by layering different materials, like foam, mineral wool, and mass-loaded vinyl, to target various sound frequencies. Place softer, porous materials near the source of noise to absorb vibrations directly. Incorporate air gaps between layers to enhance damping and reduce sound transmission. Use curved or irregular surfaces inside the enclosure to diffuse sound waves, preventing echoes. Seal all joints and seams tightly to avoid sound leaks. Consider placing absorptive materials on both the interior walls and the lid to improve overall effectiveness. Properly designing for maximum absorption guarantees quieter operation while maintaining ventilation and accessibility.

Applying Acoustic Foam or Panels

Applying acoustic foam or panels effectively requires careful placement to maximize sound absorption. First, identify the loudest areas around your pump pad and focus on those spots. Attach panels directly to walls or surfaces where sound reflects or echoes most. Use adhesive or mounting hardware suited for your material, ensuring secure placement. Cover at least 50% of the surrounding surfaces for *ideal* results, but avoid covering every inch, which can cause dead spots. Position panels at ear level or near the source to absorb noise directly. Keep in mind that uneven distribution can reduce effectiveness, so space the panels evenly. Regularly test sound levels after placement, adjusting as needed to find the best configuration for quieter operation.

Implementing Decoupling Techniques

Implementing decoupling techniques can substantially reduce vibration transmission from your pump to surrounding structures, preventing noise from amplifying or spreading. To do this, place vibration isolators like rubber pads or springs directly beneath the pump mounting points. These materials absorb and dampen vibrations before they transfer to the floor or walls. You can also mount the pump on a resilient platform or isolation base, which creates a physical barrier against vibration transmission. Additionally, avoid rigid connections between the pump and the structure; use flexible couplings or mounts instead. Ensure that all mounting points are secure but not overly tight, as this can transfer more vibration. Proper decoupling minimizes noise propagation, creating a quieter environment around your pump.

Regular Maintenance and Inspection for Noise Reduction

Regular maintenance and inspection are key to keeping your pump operating quietly over time. By regularly checking your pump, you catch issues early before they become loud problems. This proactive approach guarantees smooth operation and minimizes noise.

Here are three essential steps to follow:

- Inspect for Wear and Damage: Look for loose bolts, worn bearings, or cracks that could cause vibrations and noise.

- Lubricate Moving Parts: Proper lubrication reduces friction, preventing squeaks and rattles that disrupt quiet operation.

- Tighten and Adjust Components: Ensure all fittings and mounts are secure, preventing unnecessary vibrations that lead to noise.

Sticking to these steps keeps your pump running silently and efficiently, saving you time and stress in the long run.

Frequently Asked Questions

How Do I Identify the Main Sources of Noise From My Pump Pad?

To identify the main sources of noise from your pump pad, start by listening carefully when the pump runs. Note whether the noise comes from vibrations, rattling, or humming sounds. Check for loose connections, mounting issues, or debris that could cause vibrations. You can also gently tap or shake different parts of the pad to see which areas produce sounds, helping you pinpoint the problem sources effectively.

What Safety Precautions Should I Take When Applying Acoustic Treatments?

When applying acoustic treatments, you should prioritize safety to avoid hazards. Always wear protective gear like gloves, masks, and eye protection to prevent exposure to dust or chemicals. Turn off and unplug your equipment before starting work to prevent electrical accidents. Work in a well-ventilated area to avoid inhaling fumes. Handle tools carefully, and follow manufacturer instructions to guarantee safe and effective application of the treatments.

Can Weather Conditions Affect the Effectiveness of Soundproofing Methods?

Imagine your soundproofing as a fortress against noise, but weather’s like an unpredictable storm testing its walls. Yes, rain, humidity, and temperature swings can weaken materials or cause them to expand and contract, creating tiny gaps where sound can sneak through. To keep your fortress strong, choose weather-resistant materials, seal cracks tightly, and consider protective coatings. This way, you’ll guarantee your soundproofing remains effective no matter what Mother Nature throws your way.

Are There Eco-Friendly Soundproofing Options Suitable for Pump Pads?

You’re looking for eco-friendly soundproofing options for pump pads. You can consider using recycled rubber or cork, both sustainable and effective at absorbing noise. Plant-based materials like hemp or wool offer natural soundproofing while being eco-conscious. These options are safe for the environment, easy to install, and help reduce noise pollution. By choosing sustainable materials, you support eco-friendly practices while keeping your pump pad quieter.

How Long Does It Typically Take to See Noise Reduction Results?

Wondering how quickly you’ll notice noise diminish? Generally, you start seeing sound soften within hours to a few days after applying acoustic tricks. Patience pays off as dampening devices dampen disruptive noises gradually. By consistently using eco-friendly soundproofing methods, you’ll likely see significant silence settle in within a short span. Stay steady, and soon, the serene silence you seek will softly settle around your pump pad.

Conclusion

By applying these acoustic tricks, you’ll transform your noisy pump pad into a quieter sanctuary. Picture yourself sitting nearby, the gentle hum softened into a whisper, as soundproofing materials and vibration dampers work in harmony. With a sound-absorbing enclosure and regular check-ups, you create a peaceful oasis amid the machinery’s activity. Soon, the noise fades away like ripples calming on a still pond, giving you serenity and control over your space.