Based on my research, the VEVOR Brazed Plate Heat Exchanger stands out as the top choice for 2025, offering exceptional efficiency and durability. Its copper and 316L steel construction ensure excellent thermal performance, corrosion resistance, and long-lasting service in demanding environments. Its robust design and high pressure ratings make it suitable for various applications, especially in marine or industrial settings. Stay with me, and you’ll discover more about what makes this heat exchanger a superior option.

Key Takeaways

- Top-rated cupro-nickel heat exchangers in 2025 prioritize corrosion resistance and long-term durability in marine and seawater applications.

- The best models feature enhanced thermal efficiency through optimized plate design and turbulence-inducing patterns.

- Leading units meet or exceed high pressure ratings, ensuring safe operation in demanding industrial systems.

- They incorporate advanced sealing and brazing techniques for leak prevention and maintenance ease.

- Superior options include built-in monitoring features and design considerations for easy cleaning and extended service life.

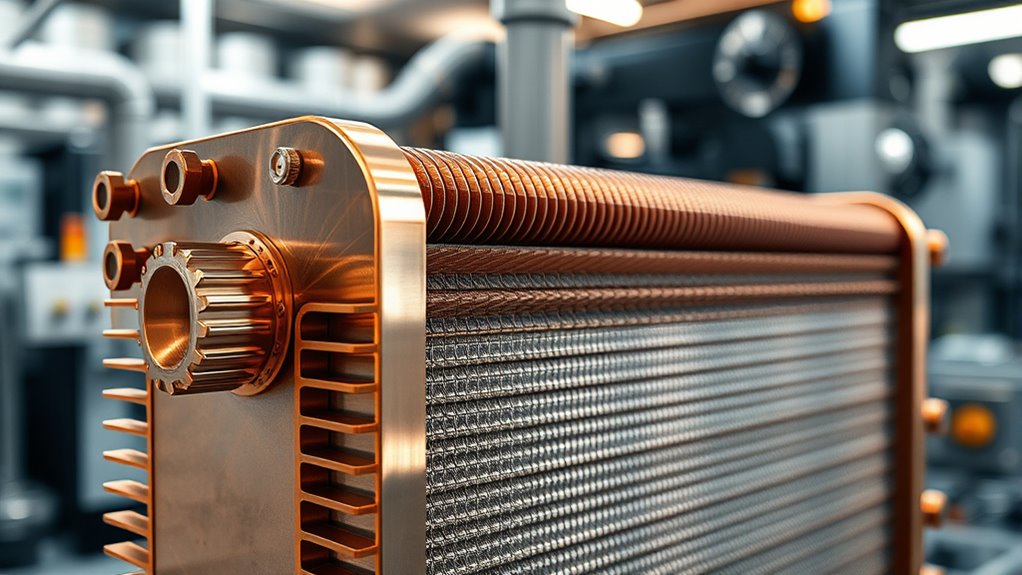

VEVOR Brazed Plate Heat Exchanger (EATB28-50, 5×12, Copper/316L Steel)

The VEVOR Brazed Plate Heat Exchanger (EATB28-50, 5×12, Copper/316L Steel) is an excellent choice if you’re looking for a high-efficiency, durable solution for heating or cooling applications. It features five stainless steel plates measuring 12×50 inches, delivering up to 99% heat transfer efficiency. Its construction from 316L stainless steel with copper brazing guarantees robustness and leak resistance. Designed to handle temperatures from -292°F to 392°F and high pressure, it’s suitable for demanding environments. Its compact size and flexible mounting options make installation straightforward, making it a reliable, long-lasting option for various thermal transfer needs.

Best For: homeowners, contractors, or facility managers seeking a high-efficiency, durable heat exchanger for applications like water heating, floor heating, snow melting, or beer cooling.

Pros:

- High heat transfer efficiency up to 99%, reducing energy costs

- Robust construction with 316L stainless steel and copper brazing for durability and leak resistance

- Compact design with flexible mounting options for easy installation

Cons:

- Some users report threading and fitting compatibility issues

- Potential for leaks or shorter lifespan if not installed properly

- Inlet and outlet ports may require additional fittings or thread tape for secure connections

Factors to Consider When Choosing Cupro-Nickel Heat Exchangers

When selecting a cupro-nickel heat exchanger, I consider several key factors to guarantee the best fit for my needs. These include material compatibility, thermal efficiency, pressure ratings, corrosion resistance, and the size and capacity required. Paying attention to these points helps me choose a reliable and efficient system.

Material Compatibility

Considering material compatibility is crucial when selecting cupro-nickel heat exchangers, as the metals in contact can considerably affect performance and longevity. Cupro-nickel alloys, containing 70-90% copper and 10-30% nickel, resist corrosion in seawater and marine environments, but compatibility with other materials is vital. Dissimilar metals can cause galvanic corrosion, damaging the system. It’s essential to choose compatible materials for components like fittings, seals, and gaskets, which must also be chemical-resistant to withstand harsh conditions. While cupro-nickel’s thermal conductivity is lower than copper’s, it’s higher than many stainless steels, influencing heat transfer. Proper material pairing ensures durability, maintains system integrity, and prevents premature failure, especially in aggressive or marine applications where corrosion resistance is imperative.

Thermal Efficiency

Have you ever wondered what factors most considerably impact the thermal efficiency of cupro-nickel heat exchangers? The design of the plates and their pattern-induced turbulence play a vital role by enhancing heat transfer. The high thermal conductivity of cupro-nickel, especially with copper’s superior heat transfer properties, boosts efficiency. The number and surface area of plates directly affect heat transfer capacity—more plates mean greater surface area. Proper sealing and brazing quality are essential to prevent leaks that can disrupt heat transfer. Additionally, operating within ideal temperature ranges and keeping plates clean and debris-free help maintain maximum efficiency over time. Paying attention to these factors guarantees you select a heat exchanger that performs reliably and efficiently throughout its lifespan.

Pressure Ratings

Pressure ratings are a crucial factor to take into account because they determine whether a cupro-nickel heat exchanger can handle your system’s operating conditions safely. They indicate the maximum pressure the unit can endure without risk of failure. For high-pressure applications, choosing a heat exchanger with a higher pressure rating ensures safety and longevity. These ratings are usually specified in psi or bar and should match or surpass your system’s operating pressure. It’s important to verify the rating includes safety margins or certifications to prevent unexpected issues. Cupro-nickel alloys generally handle pressure-induced stress well, making them suitable for demanding environments. Always confirm the pressure rating before installation to ensure compatibility and maintain system integrity over time.

Corrosion Resistance

Ever wondered why cupro-nickel heat exchangers excel in harsh environments? Their exceptional corrosion resistance is key. These alloys typically contain 70-90% copper and 10-30% nickel, creating a protective oxide layer that shields against seawater corrosion. The high copper content actively inhibits corrosion, while nickel enhances resistance to pitting and crevice corrosion common in chloride-rich settings. Additionally, cupro-nickel resists biofouling and microbial attack, making it ideal for long-term water system use. However, maintaining this corrosion resistance requires proper upkeep and avoiding exposure to chemicals that could compromise the alloy. When selecting a heat exchanger, understanding these properties ensures you choose a durable, corrosion-resistant solution capable of enduring tough environments without compromising performance.

Size and Capacity

When choosing a cupro-nickel heat exchanger, size and capacity are critical factors that directly affect its performance. A larger unit generally provides higher heat transfer capability, which is essential for meeting demanding thermal loads. Capacity ratings, typically in BTU/hr or kW, indicate the maximum heat transfer the exchanger can handle efficiently. Proper sizing involves matching the heat load requirements of your application to avoid over- or under-sizing, which can lead to inefficiency or system stress. Additionally, the physical dimensions impact installation space and system compatibility. Correct sizing ensures ideal operation, reduces energy consumption, and extends the lifespan of the heat exchanger by preventing flow issues or undue stress. Focusing on these factors guarantees reliable, efficient performance tailored to your specific needs.

Connection Types

Choosing the right connection type for your cupro-nickel heat exchanger depends on several factors that influence installation, maintenance, and system durability. Threaded fittings are common for small units, offering easy assembly and disassembly, but they require proper sealing to prevent leaks. Flanged connections provide a secure, leak-proof seal and are ideal for high-pressure applications, making future maintenance or system expansion straightforward. Soldered or brazed joints create a permanent, corrosion-resistant connection, perfect for compact systems or marine environments where reliability is critical. Your choice impacts installation complexity, long-term durability, and compatibility with existing piping. Carefully evaluate your system’s pressure, size, and maintenance needs to select the connection type that best balances ease of installation with ongoing system integrity.

Maintenance Requirements

Maintaining cupro-nickel heat exchangers requires regular inspection and cleaning to guarantee they operate at peak efficiency. I recommend routinely checking for fouling, which can hinder heat transfer, and cleaning with suitable agents to remove mineral deposits and biofilms. Although cupro-nickel’s corrosion resistance reduces maintenance needs compared to other metals, it’s still important to monitor for pitting or biofouling, especially in harsh environments. Seal and gasket inspections should be part of your routine, particularly after thermal cycling or extended operation, to detect wear or leaks early. Tailoring maintenance schedules to your specific operating conditions—fluid type, temperature, and pressure—can considerably extend the lifespan of your heat exchangers. Consistent upkeep ensures ideal performance and durability over time.

Frequently Asked Questions

How Do Cupro-Nickel Heat Exchangers Compare Environmentally to Alternatives?

You’re asking how cupro-nickel heat exchangers compare environmentally to alternatives. I’ve found they’re quite eco-friendly because they’re highly durable, reducing waste and replacement needs. Plus, their corrosion resistance means less maintenance and chemical use. While they do involve mining and processing, their long lifespan and recyclability make them a sustainable choice overall. I think they’re a solid option for those prioritizing environmental impact in heat exchange solutions.

What Are the Maintenance Requirements for Long-Term Durability?

Did you know that proper maintenance can extend a heat exchanger’s lifespan by up to 30%? For long-term durability, I recommend regular inspections for corrosion or fouling, cleaning to prevent buildup, and monitoring performance metrics. I also suggest following manufacturer guidelines for routine checks and timely part replacement. Staying proactive helps make sure your cupro-nickel heat exchanger operates efficiently and lasts longer, saving you money in the long run.

Are There Specific Industries That Benefit Most From Cupro-Nickel Materials?

When considering industries that benefit most from cupro-nickel materials, I find that maritime and seawater applications stand out. Their excellent corrosion resistance in salty environments makes them ideal for shipbuilding, marine engineering, and desalination plants. Additionally, the oil and gas sector uses cupro-nickel for heat exchangers exposed to harsh conditions. If your industry involves exposure to corrosive elements, cupro-nickel is a smart choice for durability and performance.

How Does Corrosion Resistance Vary With Different Water Qualities?

Corrosion resistance really depends on water quality. I’ve seen that in cleaner, treated water, cupro-nickel holds up well, resisting rust and degradation. But when water’s more aggressive—say, high in chlorides or pollutants—it can challenge the material’s durability. So, I always recommend testing water conditions first and choosing the right alloy, because better water quality means longer-lasting, more reliable heat exchangers.

What Innovations Are Expected to Influence Future Cupro-Nickel Heat Exchanger Designs?

Thinking ahead, I see innovations shaping cupro-nickel heat exchangers like a wave cresting on the horizon. Expect advancements in nanocoatings that boost corrosion resistance, smart sensors for real-time monitoring, and improved alloy compositions for enhanced durability. These innovations will make future designs more efficient, longer-lasting, and better suited for diverse water qualities, ensuring we stay ahead of challenges and maximize performance in demanding environments.

Conclusion

If you’re considering cupro-nickel heat exchangers, you’ll be glad to know that they can improve energy efficiency by up to 30% compared to traditional models. With durability and corrosion resistance at the forefront, I recommend the VEVOR Brazed Plate Heat Exchanger for its reliable performance. Investing in the right model not only boosts system longevity but also saves you money in the long run—making it a smart choice for 2025.