In emergency situations, you can choose between liquid chlorination and granular chlorination for water disinfection. Liquid chlorine provides rapid, even disinfection, ideal for quick responses, but requires careful handling and proper storage. Granular chlorine is easier to store and transport, dissolving quickly in water to kill pathogens effectively. Both methods are safe if used correctly, but understanding their storage, application, and safety measures helps you maximize effectiveness. If you want to know more about these methods, keep exploring the details.

Key Takeaways

- Liquid chlorination offers rapid disinfection, typically within 30 minutes, ideal for emergency responses requiring immediate results.

- Granular chlorination is easier to store and handle, with longer shelf life, suitable for situations where quick liquid deployment isn’t feasible.

- Liquid chlorine provides even dispersion and thorough contact but requires careful handling and safety protocols.

- Granular disinfectants dissolve quickly in water, allowing controlled dosing and reduced spill risks during emergencies.

- Both methods effectively kill pathogens; choice depends on urgency, storage convenience, and safety considerations.

Overview of Liquid Chlorination

Liquid chlorination involves adding liquid chlorine solutions directly into water supplies to quickly disinfect and eliminate pathogens. This method provides rapid disinfection, making it ideal for emergency situations where immediate results are needed. You typically use liquid sodium hypochlorite or chlorine gas dissolved in water for this process. The liquid is easily measurable and can be dosed precisely to match contamination levels. When you introduce the solution, it disperses evenly, ensuring thorough contact with all water parts. Liquid chlorination is favored for its quick action and straightforward application, especially in large-scale or urgent scenarios. It’s important to handle the chemicals carefully, following safety protocols, to prevent accidents. Additionally, utilizing automation can optimize dosing accuracy and enhance safety measures during the process. Proper monitoring during chlorination ensures the right concentration is maintained for effective disinfection without residual hazards. Incorporating proper safety measures is crucial to prevent exposure and ensure safe handling of chemicals during emergency chlorination. Using appropriate filtration techniques after chlorination can help remove any residual chemicals and improve water quality.

Overview of Granular Chlorination

Have you considered granular chlorination as a practical option for disinfecting water during emergencies? Granular chlorine, often in the form of calcium hypochlorite or sodium dichloroisocyanurate, is a highly effective disinfectant. It’s easy to store and transport, making it ideal for emergency situations. When added to water, the granules dissolve quickly, releasing chlorine that kills bacteria, viruses, and other pathogens. Unlike liquid chlorination, granular forms have a longer shelf life and are less prone to spills or leaks. They also allow for precise dosing, giving you control over the amount used. This flexibility helps ensure water safety without complicated equipment. Additionally, understanding Storage and handling is important to maintain the effectiveness of granular chlorine over time. Proper storage conditions can extend the shelf life and effectiveness of the chlorine. Regularly checking chlorine levels in treated water is crucial to confirm safety and effectiveness. Using storage guidelines can help prevent accidental degradation of the disinfectant. Overall, granular chlorination offers a reliable, compact, and convenient solution for emergency water treatment needs.

Application Techniques and Ease of Use

Applying granular chlorination effectively requires straightforward techniques that can be easily performed in emergency settings. First, measure the appropriate amount of granular chlorine based on the water volume and contamination level. Carefully sprinkle the granules directly into the water, ideally near the surface to promote quick dispersion. Stir the water thoroughly with a clean stick or paddle to ensure even distribution. Using turbulence during mixing can significantly improve the effectiveness of disinfection. Unlike liquid chlorination, you don’t need special equipment or precise pouring techniques, making it more accessible. After adding the granules, let the water sit for at least 30 minutes to allow proper disinfection. Keep in mind that handling granular chlorine demands caution to avoid inhalation or contact with skin. Proper mixing techniques are essential to ensure the disinfectant is evenly distributed throughout the water. Additionally, maintaining proper storage of chlorine prevents accidental spills and degradation of the disinfectant. Its ease of use makes granular chlorination a practical choice during emergency situations. Understanding the safety precautions for handling chlorine helps prevent accidents and health issues. Overall, granular chlorination is simple, fast, and effective when applied with basic safety and precision.

Storage, Shelf Life, and Handling

Proper storage and handling of chlorine are essential to keep it safe and effective. You need to follow safety guidelines to prevent accidents and ensure the chemical remains usable. Let’s explore how shelf life and storage conditions impact your emergency chlorination efforts. Additionally, understanding the storage guidelines can help maintain the chemical’s potency and safety over time. For instance, chemical stability can be influenced by environmental conditions, which is critical for ensuring effectiveness and safety. Furthermore, sound healing science indicates that proper environmental conditions can influence chemical stability and efficacy.

Storage Requirements and Safety

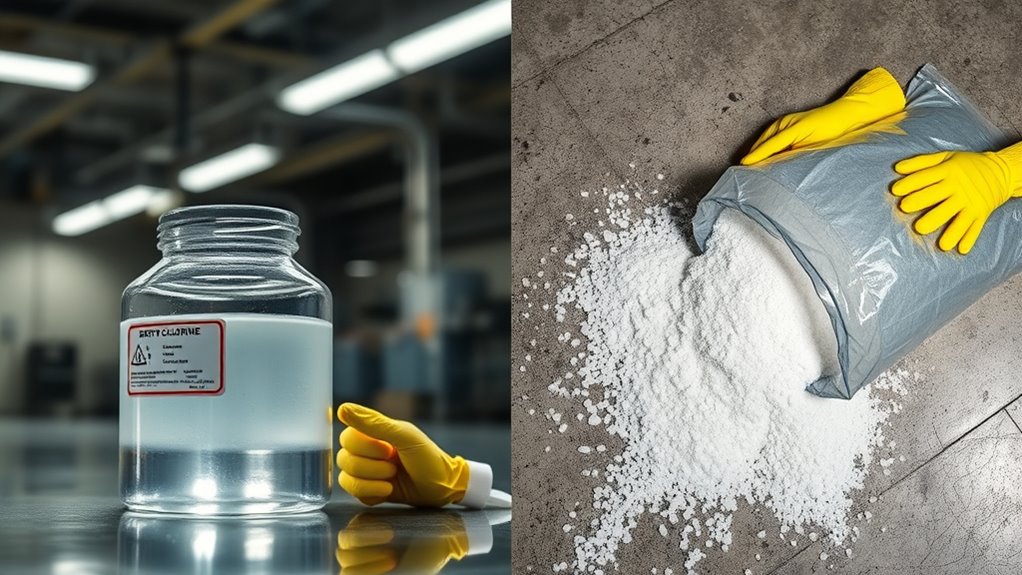

Storing chlorine safely is crucial to prevent accidents and guarantee its effectiveness. Keep liquid and granular chlorine in a cool, dry, well-ventilated area away from direct sunlight, heat sources, and incompatible materials like acids or organic compounds. Use clearly labeled, sturdy containers designed for chemical storage, and ensure lids are tightly sealed. Store chlorine separately from food, beverages, and personal items. Avoid storing large quantities in residential areas; instead, follow local regulations for storage limits. Always handle chlorine with protective gear, including gloves and goggles, to prevent contact. Regularly inspect storage containers for leaks or corrosion. Proper storage minimizes risks of spills, leaks, or chemical reactions, ensuring safety for yourself and others while maintaining the chemical’s potency. Additionally, storage requirements should be carefully followed to prevent potential hazards and ensure the chemical remains effective over time. Implementing storage best practices can further reduce the risk of accidents and preserve chemical integrity. Remember that air quality can be affected by improper storage or handling, so adherence to safety protocols is essential. Moreover, understanding the shelf life of chlorine helps in planning proper inventory management and disposal procedures. Incorporating advanced safety measures, such as proper ventilation systems, can significantly lower the risks associated with chlorine storage.

Shelf Life and Usage Tips

To guarantee chlorine remains effective and safe to use, you should pay close attention to its shelf life and handling practices. Store chlorine in a cool, dry, well-ventilated area away from direct sunlight and incompatible substances. Liquid chlorine typically has a shelf life of about 6 to 12 months if properly stored; granular chlorine can last up to 2 years under ideal conditions. Always keep containers tightly sealed to prevent contamination and evaporation. Check for discoloration, cloudiness, or unusual odors before use—these indicate degradation. When handling, wear protective gear like gloves and goggles to avoid skin and eye contact. Use chlorine promptly within its recommended lifespan, and avoid mixing different types to prevent dangerous reactions. Proper storage and timely usage ensure safe, effective chlorination. Regularly monitor and inspect your chlorine storage area to maintain optimal storage conditions and prolong its efficacy. Additionally, maintaining proper ventilation in storage areas can help prevent the buildup of potentially hazardous fumes.

Effectiveness and Disinfection Speed

Emergency chlorination methods are highly effective at rapidly disinfecting contaminated water, making them essential in urgent situations. Liquid chlorine acts quickly, providing immediate disinfection once added, often within 30 minutes. It’s easy to measure and adjust, ensuring you can respond swiftly to contamination. Granular chlorine, on the other hand, dissolves more slowly, but still offers rapid results when properly prepared. Both methods kill bacteria, viruses, and other pathogens effectively, but liquid tends to act faster due to its immediate availability. Your choice depends on the situation: liquid chlorine offers quicker disinfection, while granular requires a bit more preparation but remains reliable. Overall, both methods deliver fast, effective pathogen removal, ensuring water safety during emergencies.

Environmental and Safety Considerations

When using emergency chlorination, you need to be aware of chemical spill risks and ensure proper handling and storage to prevent accidents. You also have to consider the environmental impact, such as how residual chlorine might affect nearby ecosystems. Staying informed about safety protocols helps protect both you and the environment during chlorination efforts.

Chemical Spill Risks

Chemical spill risks during emergency chlorination procedures pose significant environmental and safety challenges. Spills can contaminate soil, water sources, and harm nearby ecosystems if not managed carefully. You need to be vigilant when handling liquid or granular chlorine, as accidental releases can cause chemical burns or respiratory issues. Proper containment and cleanup protocols are vital to minimize damage and protect personnel. Quick response is essential to prevent the spread of chemicals and environmental contamination.

- Use spill containment pallets or barriers to contain leaks

- Wear appropriate personal protective equipment (PPE) at all times

- Have spill cleanup kits readily available

- Ensure proper training for emergency response procedures

Handling and Storage Safety

Proper handling and storage of chlorination chemicals are essential to prevent accidents and environmental harm. Always keep chemicals in clearly labeled, tightly sealed containers away from incompatible substances. Store them in cool, dry, well-ventilated areas, away from heat sources and direct sunlight. Use secondary containment like spill trays to contain leaks or spills. When handling, wear appropriate personal protective equipment such as gloves, goggles, and respirators to avoid skin and eye contact. Limit access to authorized personnel trained in safe procedures. Regularly inspect storage areas for leaks, corrosion, or damage. Keep emergency equipment, like spill kits and neutralizing agents, nearby. By following proper handling and storage protocols, you reduce the risk of accidents and protect both personnel and the environment.

Environmental Impact

Have you considered how emergency chlorination methods can impact the environment and safety? Using liquid or granular chlorine can introduce risks if not managed properly. Liquid chlorine releases toxic gases if spilled, posing inhalation hazards, while granular chlorine can cause soil and water contamination if improperly disposed of. Both methods can harm aquatic life if chlorinated runoff enters water bodies. Proper handling minimizes environmental damage and personal risk. You should always follow safety protocols to prevent leaks and spills. Additionally, consider the long-term effects of residual chemicals on ecosystems. Being aware of these impacts helps you make informed decisions, reducing ecological harm and ensuring safety during emergency responses. Protecting the environment is a key part of responsible chlorination.

Frequently Asked Questions

Which Chlorination Method Is More Cost-Effective Long-Term?

You’re asking which chlorination method is more cost-effective long-term. Typically, liquid chlorination offers lower initial costs and easier handling, but granular chlorination often proves more economical over time due to its longer shelf life and lower labor needs. Consider your facility’s specific requirements, storage capabilities, and maintenance costs. Evaluating these factors helps you decide which method aligns best with your budget and operational needs for sustained, cost-effective disinfection.

How Do Weather Conditions Impact Chlorination Effectiveness?

Weather conditions act like an unpredictable tide, influencing how well chlorination works. Rain can wash away disinfectants, diluting their power, while sunlight’s UV rays can break down chlorine faster, weakening its shield. Wind can disperse chlorinated water, reducing contact time. You need to adapt your approach based on weather, ensuring your chlorination remains a steadfast guardian despite nature’s shifting moods, keeping water safe and clean.

Can Granular Chlorination Be Used in Emergency Water Supplies?

You can definitely use granular chlorination in emergency water supplies. It’s effective because it dissolves quickly and provides a strong disinfectant dose. Just guarantee you measure the correct amount based on water volume, and mix it thoroughly. Granular chlorination is especially useful when liquid options aren’t available or practical. Always follow safety guidelines to prevent over-chlorination, and allow sufficient contact time for effective disinfection.

Are There Specific Regulatory Standards for Each Chlorination Type?

You ask if there are specific regulatory standards for each chlorination type. Regulations vary by region, but generally, agencies like the EPA set standards for chlorination practices, including allowable concentrations and safety measures. Both liquid and granular chlorination methods must meet these standards to guarantee water safety. You should always check local regulations to make sure your chosen method complies, as proper handling and dosing are essential for effective disinfection and safety.

What Are the Health Risks Associated With Improper Chlorination?

You should know that improper chlorination can pose health risks like skin and eye irritation, stomach issues, or even more severe conditions if the water contains too much residual chlorine or harmful byproducts. When chlorination isn’t properly controlled, you risk exposing yourself to these hazards. Always follow safety guidelines, verify proper dosing, and monitor chlorine levels to protect your health and prevent waterborne illnesses.

Conclusion

Choosing between liquid and granular chlorination depends on your needs, your environment, and your safety. Whether you prioritize quick application, ease of storage, or environmental impact, understanding these methods helps you make informed decisions. Weigh the effectiveness against safety, convenience against stability, and speed against handling. Ultimately, your choice should align with your goals, your resources, and your commitment to safe, effective water disinfection. Make your decision wisely, act confidently, and guarantee safe, clean water every time.