To set up and tune your chemical automation feeder, start by inspecting components for damage, guaranteeing supply lines and connections are secure and leak-free. Install and calibrate pumps and flow meters to match your process needs. Fine-tune flow rates through calibration, monitor output stability, and adjust as necessary for accuracy. Regular maintenance and performance checks help keep everything working smoothly. Keep going to discover detailed steps that ensure your system operates reliably and precisely.

Key Takeaways

- Verify proper installation of chemical containers, supply lines, and injection points according to manufacturer instructions.

- Calibrate flow rates using calibration mode to ensure accurate chemical dosing.

- Adjust flow controls and pump speeds incrementally based on system feedback for optimal performance.

- Regularly monitor system metrics like pressure, flow, and chemical levels to detect issues early.

- Maintain detailed logs of setup, calibration, and adjustments to support system reliability and troubleshooting.

Assessing Your Chemical Feeder System and Preparing for Setup

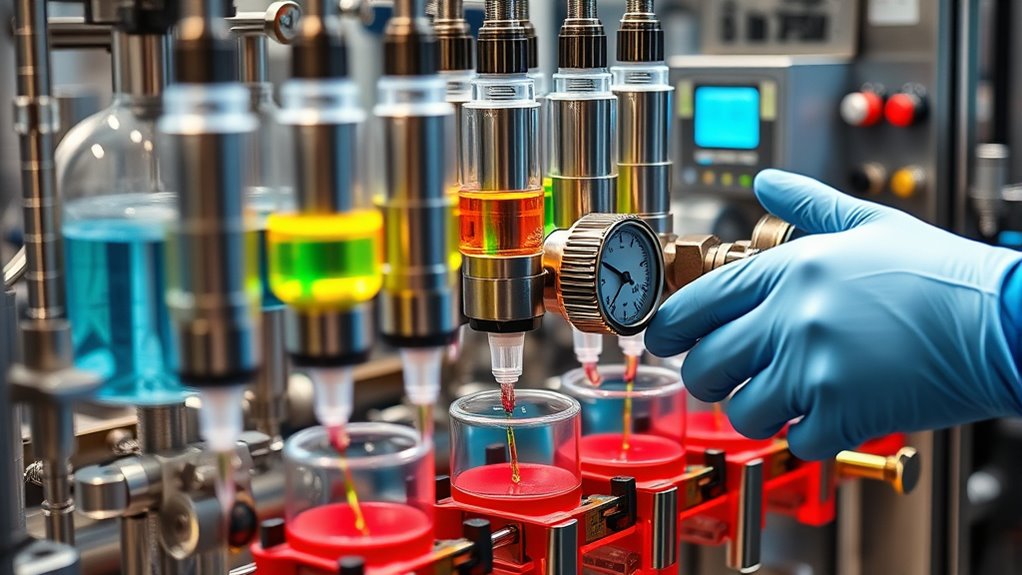

Before setting up your chemical feeder system, you need to thoroughly assess its current condition and guarantee all components are ready for installation. Start by inspecting each part for damage, corrosion, or wear that could affect performance. Check the supply lines, valves, and pump for leaks or blockages. Make sure the chemical containers are clean and properly labeled. Confirm that power sources and control units are functional and compatible with your system’s specifications. Review the manufacturer’s instructions to ensure all parts are present. Evaluate the system’s contrast ratio to understand its ability to render detailed images in low-light conditions. Additionally, verifying the system calibration can prevent inaccuracies in chemical delivery and ensure optimal operation. Monitoring the cheating tendencies of system components can also help in diagnosing potential malfunctions before they impact performance. Conducting a thorough performance assessment can further identify areas needing improvement prior to setup. Incorporating regular mindfulness checks during assessment can help maintain focus and ensure thoroughness throughout the process.

Installing and Connecting Your Chemical Feeder Components

To guarantee your chemical feeder system operates effectively, start by carefully installing and connecting each component according to the manufacturer’s instructions. Begin with the chemical container, ensuring it’s secured and positioned at the correct height. Attach the inlet tubing securely, checking for leaks or kinks that could impede flow. Connect the pump to the power source, making sure all electrical connections are safe and properly insulated. Install the injection point, verifying it’s correctly positioned within the system to deliver chemicals accurately. If your setup includes valves or flow meters, install them as specified, ensuring they operate smoothly. Double-check all fittings and connections for tightness. Proper installation at this stage prevents leaks, ensures safe operation, and lays the foundation for effective system performance. Additionally, understanding the importance of proper setup and maintenance helps in optimizing the system’s longevity and reliability. Regular inspections and system calibration are crucial for maintaining consistent chemical dosing and preventing issues. Paying attention to system performance ensures your system continues to operate efficiently over time. Moreover, incorporating sound engineering principles can further enhance the safety and efficiency of your setup.

Configuring the Initial Settings and Calibration Procedures

Once you’ve securely installed and connected all components, the next step is to configure the initial settings and calibrate your chemical feeder system. Start by setting the flow rates according to your desired chemical dosing levels, referencing manufacturer guidelines. Next, power on the system and verify it’s ready for calibration. Use the calibration mode or manual controls to dispense a known volume of chemical—this helps you confirm accuracy. Additionally, understanding asset division principles can aid in planning for future system upgrades or replacements, ensuring equitable resource allocation. Adjust the flow rate controls until the dispensed amount matches your target. Record these initial settings for future reference. Confirm that the system maintains consistent flow without fluctuations. Proper calibration ensures your system delivers chemicals accurately from the start, laying a solid foundation for ongoing fine-tuning and precise operation. Furthermore, regularly monitor performance metrics, such as pressure stability and flow consistency, to detect any deviations early and maintain optimal operation over time. Implementing regular maintenance routines can also help prevent unexpected malfunctions and extend the lifespan of your equipment. Regularly checking for leakages can also prevent costly malfunctions and ensure safety during operation.

Fine-Tuning Chemical Dosing for Accuracy and Consistency

Achieving precise and consistent chemical dosing requires careful fine-tuning after initial calibration. Start by closely monitoring the output over several cycles, noting any deviations from your target dosage. Adjust flow rates or pump speeds incrementally, making small changes to avoid overshooting. Check for any mechanical issues, such as clogging or leaks, that could affect accuracy. Confirm your control system responds correctly to setpoint adjustments, verifying that the feedback loop functions smoothly. Record each modification and its impact to create a clear adjustment trail. Remember, patience is key—small, deliberate tweaks lead to better consistency. Regularly verify dosing accuracy, especially after maintenance or changes, to maintain reliable operation over time. Additionally, understanding Gold IRA Rollovers can provide insights into diversifying your investment portfolio to ensure greater long-term financial stability. Incorporating precise calibration techniques can further enhance dosing accuracy and system reliability, especially by utilizing advanced sensors for real-time feedback and improved measurement precision.

Monitoring Performance and Making Adjustments for Optimal Operation

Effective performance monitoring involves consistently observing your chemical feeders during operation to identify any deviations from desired dosing levels. Regular checks help you catch issues like clogging, leaks, or inaccurate flow rates early. To maximize operation, track key indicators such as flow consistency, pressure, and chemical levels. Use these observations to make informed adjustments, ensuring precise dosing. Consider implementing a simple log to record performance and adjustments over time. This helps identify patterns and prevent recurring problems. Be proactive in maintaining your system by cleaning nozzles, tightening fittings, or recalibrating sensors as needed. Implementing preventative maintenance routines can further enhance system longevity and performance. Incorporating real-time analytics can provide immediate feedback, allowing for quicker response to any anomalies. Regular monitoring and prompt adjustments keep your chemical feeders running efficiently, reducing waste and ensuring optimal water quality. Staying vigilant ensures your system operates reliably and delivers consistent results.

Frequently Asked Questions

What Safety Precautions Should I Consider During Chemical Feeder Installation?

When installing a chemical feeder, you should prioritize safety to prevent accidents. Always wear appropriate personal protective equipment like gloves, goggles, and aprons. Make certain the power source is disconnected before starting. Work in a well-ventilated area, and handle chemicals carefully to avoid spills or fumes. Follow manufacturer instructions, check for leaks, and double-check connections. Properly secure the equipment to prevent movement or tipping, keeping safety your top priority throughout the process.

How Often Should Chemical Feeders Be Serviced or Recalibrated?

You should service or recalibrate your chemical feeders regularly to guarantee peak performance. Typically, it’s recommended to check them at least once every three to six months, but this can vary based on usage and manufacturer guidelines. Keep an eye out for inconsistent chemical output or alarms, and perform calibration more frequently if you notice issues. Regular maintenance helps prevent downtime and maintains safe, accurate chemical dosing.

What Common Issues Cause Inaccurate Chemical Dosing?

When it comes to inaccurate chemical dosing, you’ll often find issues like clogged nozzles, incorrect calibration, or worn-out parts causing problems. You might also experience flow rate fluctuations or air leaks that disrupt proper dosing. Regularly inspecting and maintaining your system helps. Keep an eye on sensor readings and make sure your calibration is up-to-date, so you avoid dosing errors and keep everything running smoothly.

Can Chemical Feeders Handle Multiple Chemicals Simultaneously?

Imagine juggling a few balls at once—you can do it smoothly with practice. Similarly, chemical feeders can handle multiple chemicals simultaneously, but it requires careful setup and calibration. You’ll need to guarantee each chemical’s flow rate and compatibility are properly managed to prevent cross-contamination or inaccurate dosing. With proper tuning and maintenance, your system can efficiently dispense multiple chemicals, keeping your process running smoothly without missing a beat.

What Troubleshooting Steps Are Recommended for Inconsistent Dosing?

When dealing with inconsistent dosing, you should start by checking the chemical levels in the feeder to guarantee they’re adequate. Next, verify that the pump is operating correctly and not clogged or worn out. Inspect the calibration settings and adjust if needed. Look for any blockages in the lines or valves, and clean or replace components as necessary. Regular maintenance and monitoring will help maintain consistent dosing performance.

Conclusion

By carefully evaluating, installing, and fine-tuning your chemical feeder system, you ensure reliable and accurate dosing. Did you know that improper calibration can lead to up to 30% over- or under-dosing? Staying vigilant with monitoring and adjustments keeps your system efficient and safe. Regular maintenance and calibration not only improve performance but also extend your equipment’s lifespan—so stay proactive, and your chemical automation will run smoothly and effectively every time.