A well-planned equipment pad layout saves you time and money now and in the future. By properly sizing, positioning utilities for easy access, ensuring adequate drainage and ventilation, and leaving room for expansion, you prevent costly repairs and maintenance delays. Choosing durable materials and collaborating with contractors helps achieve a reliable, organized setup. To maximize efficiency and protection, several key design considerations come into focus — learn more about creating the perfect layout to future-proof your investment.

Key Takeaways

- Proper planning ensures easy access, safety, and future expansion, reducing costly adjustments and repairs.

- Strategic placement of utilities and equipment optimizes space and simplifies maintenance.

- Using durable materials and proper drainage extends equipment lifespan and minimizes environmental impact.

- Leaving adequate clearance and pathways prevents obstructions and facilitates repairs and upgrades.

- Collaborating with contractors during installation guarantees alignment with design goals and future needs.

Why Proper Equipment Pad Planning Saves You Time and Money

Proper equipment pad planning can considerably reduce installation delays and unexpected costs. When you carefully evaluate ground stability beforehand, you prevent future issues like shifting or sinking that could require costly repairs or adjustments. A well-designed pad ensures your equipment remains level and secure, avoiding downtime and maintenance expenses. Additionally, thoughtful planning enhances the aesthetic appeal of your setup, making it look professional and integrated with your property. By taking the time to choose the right materials and layout early on, you save money and avoid the hassle of redesigning or relocating equipment later. Incorporating ground stability assessments into your planning process is key to long-term success. Ensuring that your pad accounts for proper drainage can prevent water accumulation and potential erosion issues, further extending the lifespan of your setup. Considering soil composition during planning can help you select the most suitable foundation for your needs. Conducting a site survey can provide valuable insights into existing conditions and potential challenges before construction begins. Paying attention to local regulations and permits also helps avoid legal complications and project delays. Clear planning streamlines the installation process, saving you time and resources while guaranteeing your equipment functions effectively for years to come.

Essential Factors to Consider When Designing Your Equipment Pad

When designing your equipment pad, you need to focus on space optimization to guarantee everything fits comfortably without clutter. Utility and accessibility are also vital, so you can easily connect services and maintain your equipment. By considering these factors early, you set the foundation for a safe, functional, and efficient setup. Additionally, understanding the color accuracy beneficial for specific health concerns can guide you in creating a space that promotes well-being and comfort. Incorporating proper lighting can further enhance visibility and safety within your equipment area. Ensuring the environment supports ergonomic design can also contribute to long-term comfort and productivity. Paying attention to proper ventilation is essential to prevent overheating and maintain air quality in your setup.

Space Optimization Strategies

Effective space optimization is crucial for designing an equipment pad that functions efficiently and complies with safety standards. You should plan utility placement carefully to minimize clutter and guarantee easy access for maintenance. Position utilities in a way that maximizes available space without interfering with equipment operation. Aesthetic considerations also matter; a clean, organized layout not only looks professional but helps you identify issues quickly. Use a logical arrangement that balances accessibility with compactness, avoiding unnecessary gaps or overcrowding. Think about future expansion—leaving room for additional equipment or upgrades. Incorporating space planning principles can further improve the overall efficiency of your setup. By focusing on these strategies, you create a streamlined setup that simplifies daily operations, reduces risks, and saves time and money in the long run. Incorporating herbalism principles into your planning can promote a healthier and more sustainable environment around the equipment area.

Utility and Accessibility

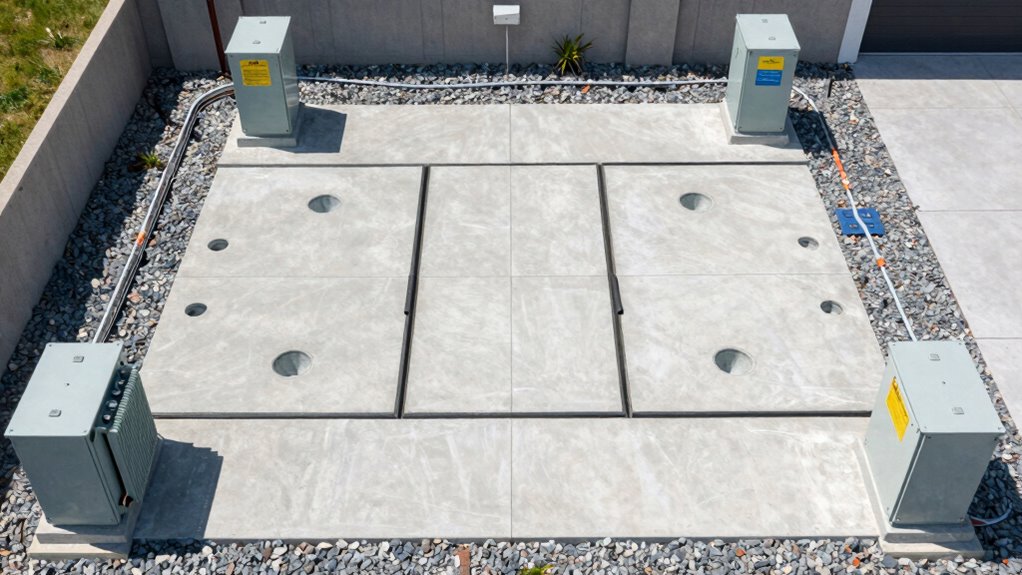

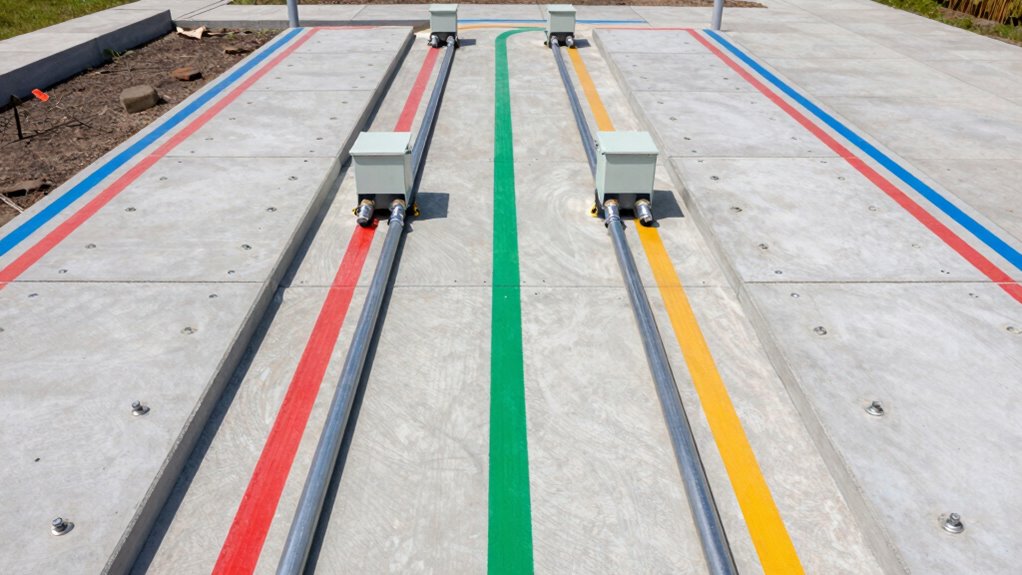

Designing your equipment pad requires careful attention to utility placement and ease of access. Proper utility planning ensures that all connections—power, water, gas—are conveniently located and organized for future maintenance. Accessibility features are essential for safe and quick servicing, reducing downtime and frustration. Consider clear pathways and sufficient space around equipment for technicians. Incorporate features like:

- Adequate clearance for repairs and inspections

- Properly labeled utility connections

- Accessibility ramps or level surfaces

- Strategic placement to minimize wiring and piping runs

- Effective utility organization enhances overall setup efficiency and simplifies troubleshooting. Ensuring your cabling and wiring are neatly organized and protected also contributes to the overall efficiency of your setup. Paying attention to utility accessibility helps prevent potential hazards and streamlines maintenance tasks. Incorporating standardized utility connections can further streamline future upgrades and repairs. Thoughtful utility planning and systematic layout contribute to a safer and more reliable setup. Focusing on utility and accessibility not only simplifies ongoing maintenance but also extends the lifespan of your equipment. A thoughtfully designed pad saves time and effort, making future adjustments straightforward and hassle-free.

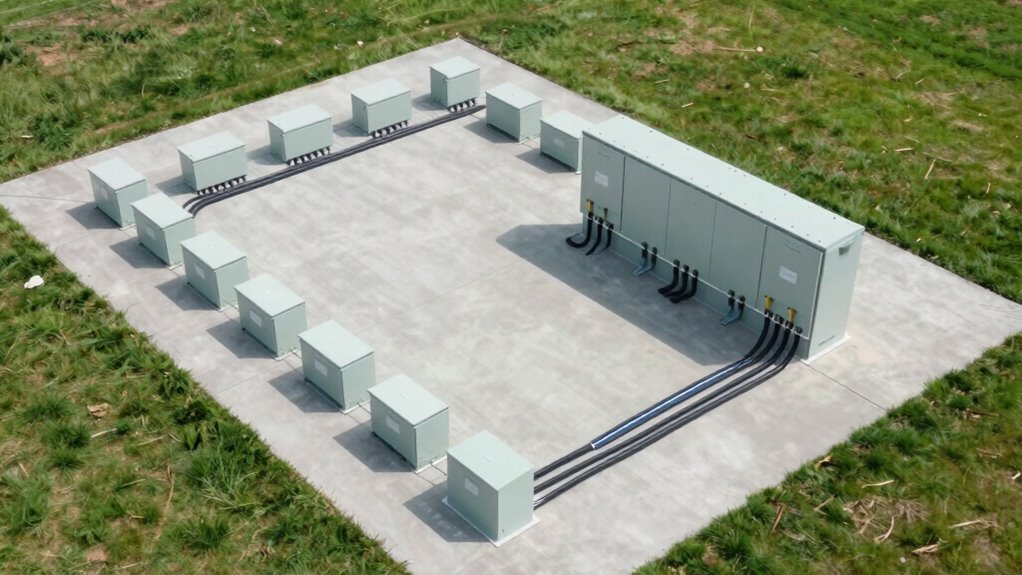

How to Determine the Right Size and Shape for Your Equipment Pad

Choosing the right size and shape for your equipment pad is crucial to guarantee stability, safety, and proper functioning. Start by evaluating the equipment’s dimensions and future expansion needs to ensure enough space for installation and maintenance. Consider equipment safety by providing adequate clearance around units to prevent overheating and facilitate repairs. Proper clearance is essential for safe operation and long-term reliability. The shape should promote even load distribution and minimize environmental impact, such as runoff or soil disruption. Opt for a rectangular or square pad when dealing with multiple units to simplify layout and reduce waste. Avoid overly compact designs that compromise stability or safety. Remember, a well-sized, appropriately shaped pad reduces stress on the equipment, enhances durability, and minimizes environmental harm, setting a solid foundation for long-term performance. Incorporating extension cord standards and weatherproofing practices can further enhance safety and reliability.

Best Practices for Equipment Placement to Maximize Accessibility and Maintenance

Proper equipment placement directly impacts how easily you can access and maintain your units over their lifespan. To maximize accessibility, position equipment with clear pathways, avoiding tight corners or obstructions. Keep maintenance points accessible without moving other units. Guarantee equipment security by placing units where unauthorized access is difficult but still reachable when needed. Consider aesthetic considerations to create a tidy, professional look that discourages tampering and enhances property value. Additionally, understanding dream symbolism related to clocks or time can inspire thoughtful placement that reflects harmony and balance in your environment. Remember that safety precautions are essential when setting up your equipment to prevent accidents and ensure long-term functionality. Paying attention to equipment durability can further ensure your setup remains reliable over time.

Drainage and Ventilation Tips for a Durable Equipment Pad

To guarantee your equipment pad lasts, you need to focus on proper drainage planning so water won’t pool or cause damage. Adequate ventilation strategies are equally important to prevent overheating and moisture buildup. Implementing these tips helps keep your equipment protected and functioning reliably over time.

Proper Drainage Planning

Effective drainage is essential for ensuring your equipment pad remains durable and functions properly over time. Proper drainage planning prevents water accumulation that can cause damage or reduce lifespan. Focus on stormwater management techniques that direct water away from the pad efficiently. This minimizes environmental impact and protects your equipment. Consider these key strategies:

- Slope the pad slightly to facilitate runoff

- Install a gravel base for quick water infiltration

- Use perforated pipes for drainage channels

- Incorporate erosion control measures like silt fences

Adequate Ventilation Strategies

Ensuring your equipment pad has adequate ventilation is essential for preventing heat buildup and moisture accumulation, both of which can damage your equipment over time. Implement effective ventilation systems that promote proper airflow management, such as installing vents or exhaust fans if needed. These systems help dissipate heat generated by your equipment and reduce humidity, minimizing corrosion and electrical issues. Proper airflow management also involves spacing equipment appropriately and avoiding obstructions that block ventilation paths. Regularly inspecting vents and fans guarantees they function correctly. By prioritizing ventilation strategies, you protect your investment and extend the lifespan of your equipment. Good airflow management is a simple yet vital step in creating a durable, reliable equipment pad that performs optimally for years to come.

Common Equipment Pad Layout Mistakes and How to Avoid Them

One of the most common mistakes in equipment pad layout is placing components too close together, which can lead to accessibility issues and maintenance difficulties. This tight spacing hampers quick service and may compromise equipment security if access is blocked. To avoid this, consider these points:

- Ensure enough space for easy maintenance and repairs

- Maintain clear pathways for technicians and emergency access

- Balance aesthetic considerations with functional spacing

- Keep security in mind by preventing unauthorized access or tampering

Planning for Future Expansion in Your Equipment Setup

Planning for future expansion is essential to avoid costly redesigns and rework down the line. Start with utility planning by leaving extra space and guaranteeing your electrical, water, and other connections can handle additional equipment. This foresight saves money and minimizes disruptions later. Also, consider aesthetic considerations; a well-organized layout now makes future additions seamless and visually appealing. Position your current equipment to allow easy access for future upgrades or new installations without overcrowding. Think about pathways, clearance, and the overall look of your setup. By integrating these strategies during initial planning, you create a flexible, efficient space that adapts easily to growth, saving you time and expenses down the road. Proper foresight now assures your equipment pad remains functional and attractive in the future.

Choosing the Best Materials for a Long-Lasting Equipment Pad

Selecting the appropriate materials for your equipment pad is essential to guarantee durability and long-term performance. Your materials selection should focus on durability factors that withstand environmental conditions and heavy use. Opt for high-quality concrete reinforced with steel for strength and stability. Consider gravel or crushed stone base layers to promote drainage and prevent shifting. Use weather-resistant sealants to protect the surface from moisture and cracking. Additionally, ensure the materials are compatible with future expansion plans, avoiding unnecessary replacement costs. Key durability factors include resistance to freeze-thaw cycles, load-bearing capacity, and minimal maintenance needs. Proper material choice guarantees your equipment pad remains stable, functional, and safe over time. Making informed decisions now saves you headaches and expenses down the road.

Sketching Your Equipment Pad Layout: A Step-by-Step Guide

To start sketching your equipment pad layout, gather all the necessary tools like a ruler, pencil, and measuring tape. Begin by drafting a rough layout sketch that includes key equipment placements and clearances. Review your draft, make adjustments as needed, and guarantee everything fits within your space and meets safety requirements.

Gather Necessary Tools

Before you start sketching your equipment pad layout, gather the essential tools you’ll need to make the process smooth and accurate. Having the right supplies guarantees your measurements are precise and your design is clear. Make certain to include tools that support proper tool storage, so everything stays organized. Prioritize safety measures by choosing tools with secure grips and protective features. Here are some key tools to gather:

- Tape measure for accurate dimensions

- Graph paper or a digital drawing app for sketching

- Ruler or straightedge for clean lines

- Pencils or markers for easy adjustments

These tools help you create a detailed, safe, and efficient layout, preventing mistakes and saving you time in the future. Proper preparation with the right tools is a vital step toward a successful equipment pad setup.

Draft Layout Sketch

Have you ever wondered how to turn your measurements and ideas into a clear, visual plan? Start by sketching a draft layout of your equipment pad, focusing on landscaping aesthetics and color coordination. Use quick, freehand drawings to map out where each piece of equipment will go, paying attention to spacing and flow. Incorporate elements like plant beds or decorative borders to enhance visual appeal, ensuring they complement your overall landscaping style. Keep your sketch simple but detailed enough to visualize the setup. This draft acts as a blueprint, helping you identify potential issues early. Don’t worry about perfection—your goal is to get a tangible sense of how everything fits together, making adjustments easier before moving to the final plan.

Review and Adjust

Ever wondered how to guarantee your equipment pad layout works smoothly? Review and adjust your sketch carefully before finalizing. Check that utility access points are unobstructed and easily reachable, avoiding future complications. Make certain the layout promotes a clean, aesthetic design that blends with your property. Consider these key points:

- Confirm all utility access aligns with existing infrastructure

- Optimize spacing for future maintenance needs

- Balance functionality with visual appeal

- Adjust for any unexpected obstacles or site conditions

Working With Contractors to Get Your Equipment Layout Just Right

Collaborating effectively with contractors is essential to guarantee your equipment layout is both functional and efficient. Clear contractor communication helps you convey your vision, especially when balancing landscaping aesthetics with practical needs. Start by discussing your goals upfront and sharing detailed plans or sketches. Ask contractors for input on space utilization, ensuring that equipment placement doesn’t compromise your landscape’s beauty. Be specific about access points, power sources, and future maintenance. Regular check-ins during installation prevent misunderstandings and allow adjustments. Remember, a good contractor values your input and endeavors to match your aesthetic preferences while maintaining operational efficiency. By working closely together, you ensure your equipment pad layout not only works well but also complements your overall landscape design.

Frequently Asked Questions

What Permits Are Required for Installing an Equipment Pad?

You’ll need to check permit requirements for installing an equipment pad, as local regulations vary. Usually, you must obtain a building or zoning permit from your local authority before starting. Contact your city or county office to confirm specific documentation and approval processes. Securing these permits guarantees your installation complies with safety standards and avoids fines or delays, making future maintenance and upgrades smoother.

How Does Climate Impact Equipment Pad Design Choices?

Imagine your equipment pad standing firm against fierce sun or relentless rain. Climate considerations influence your design choices—think sturdy materials and proper drainage. You need weatherproofing solutions like sealed enclosures or elevated pads to prevent water damage and temperature extremes. By adapting your setup to local weather, you protect your equipment and extend its lifespan, ensuring reliable performance no matter what Mother Nature throws your way.

Can I Customize Equipment Pad Dimensions for Unique Equipment?

Yes, you can customize equipment pad dimensions for unique equipment. Pad customization allows you to tailor the size and layout to fit specific needs, ensuring ideal space utilization and accessibility. With dimension flexibility, you can accommodate diverse equipment types and future upgrades. This proactive approach minimizes rework and streamlines installation, saving you time and money while making sure your setup is perfectly suited for your equipment’s requirements.

How Do I Ensure Safety Around the Equipment Pad?

To guarantee safety around your equipment pad, you should clearly display safety signage, install protective barriers, and keep the area well-maintained. You can prevent accidents by marking hazards, restricting unauthorized access, and regularly inspecting the setup. Maintain a neat, organized space by removing debris and ensuring barriers are sturdy. This proactive approach helps safeguard everyone, minimizes risks, and promotes a safe environment for future use.

What Maintenance Routines Are Recommended for Installed Pads?

You should follow a maintenance checklist and perform routine inspections regularly to keep your installed pads in top shape. Check for cracks, erosion, or shifts that might compromise stability. Clean debris and make certain drainage is clear. Lubricate moving parts if applicable and tighten any loose bolts. Regular upkeep prevents costly repairs and prolongs equipment lifespan. Schedule inspections monthly or after severe weather to maintain safety and performance.

Conclusion

A well-designed equipment pad may seem small now, but it’s the foundation for your future efficiency and savings. While rushing the setup might save time today, neglecting proper planning can lead to costly repairs or adjustments later. Think of your pad as the backbone of your system—invest wisely upfront, and you’ll enjoy seamless operation and peace of mind for years to come. After all, what’s built today shapes tomorrow’s success.